WHY FORTIPHY™ XVD?

because conventional PVD is old technology

The high-failure rate of conventional PVD coatings is expensive. It’s time for a new generation of surface enhancement: Phygen’s FortiPhy™ XVD Nanoperfection Technology is a quantum leap ahead of conventional cathodic arc PVD coatings.

a breakthrough scientific advance

FortiPhy™ XVD (Xcelerated Vapor Deposition) Nanoperfection Technology delivers smaller, more consistent nanoparticles while eliminating 90% of the macroparticle flaws and surface defects common to conventional PVD surface coatings. The nearly defect-free nanocrystalline structure produced by FortiPhy™ XVD Technology is far superior to conventional PVD, delivering levels of performance and endurance never before thought possible.

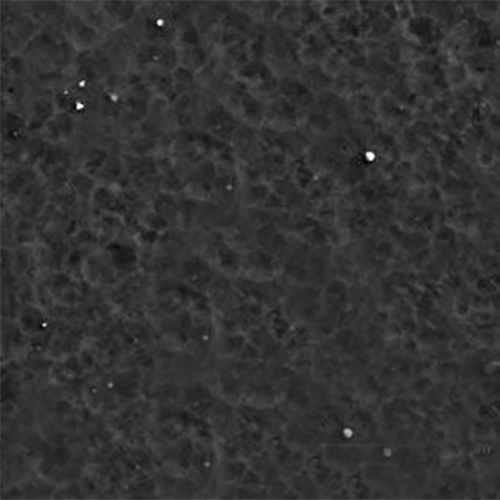

FORTIPHY™ XVD NANOperfection

Nearly defect-free

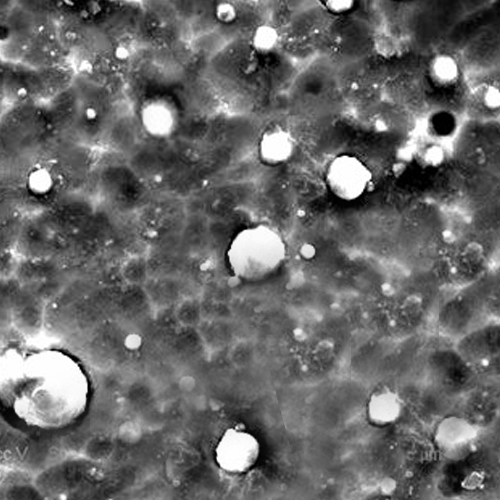

Conventional PVD coating

Many macro particle defects

welcome to true ultra-endurance

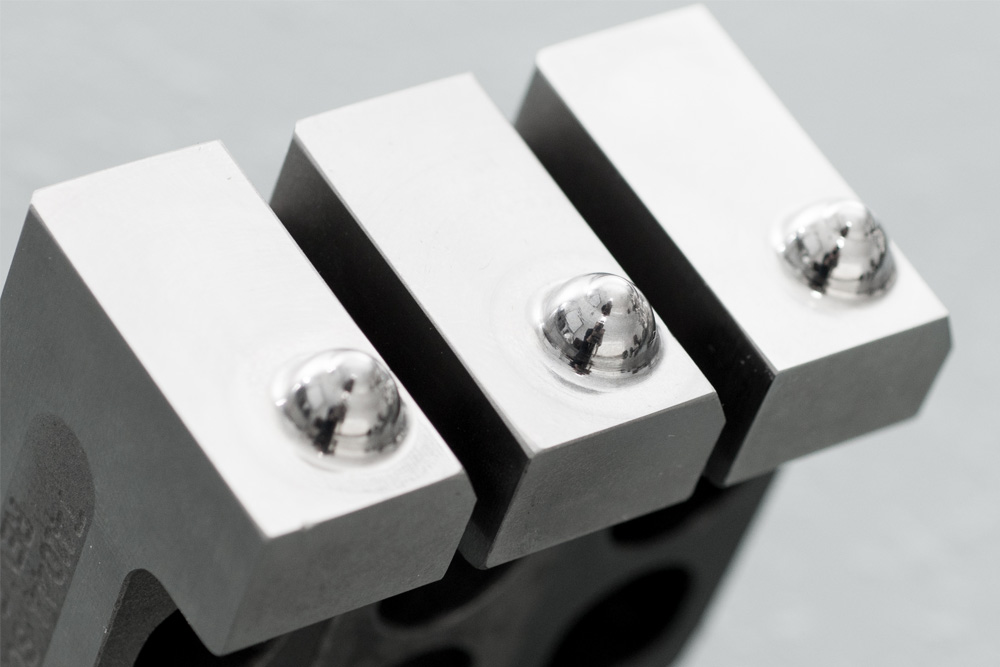

No other coating technologies can even come close to the performance characteristics and ultra-endurance provided by Phygen’s FortiPhy™ XVD technology. You have to see it to believe it.

scientifically proven ultra-endurance

lasts 3x to 88X longer than conventional PVD coatings

ultra hard = superior wear resistance

The FortiPhy™ XVD process delivers near-diamond hardness, shielding even the hardest substrate materials. Its higher surface density and tighter nano-crystalline structure delivers the lower surface energy required for higher lubricity, smoother sliding and faster release needed in high-speed applications.

super bond strength = extended longevity

Proven in the lab and in real use application, the FortiPhy™ XVD surface bond strength is stronger than the molecular bond of the substrate material itself, significantly reducing the peeling, cracking and scratching responsible for most coating failures.

ultra thin = dimensional precision

Depending on the application, FortiPhy™ XVD coatings have different engineered thicknesses (3 to 6 microns). For reference a human hair is about 70 microns thick. FortiPhy™ XVD coating thicknesses are precise and controlled, providing exact conformance to fine surface details so tighter tolerances can be met and intended dimensions of components can be preserved.

corrosion protection = consistent results

Industry standards for corrosion resistence (e.g. electroless nickel) are soft and wear away quickly. FortiPhy™ XVD coatings are inert and won’t cause an increased risk of any chemical reactions. Phygen is proud to announce it’s FortiPhy™ technology has been bench-tested by the US Army and designated a leader in corrosion protection for high pressure, highly abrasive environments.

non-toxic, earth-friendly

green is good

FortiPhy™ nanoparticle compounds are comprised of a completely inert and safe molecule which is deposited in a chemical-free process inside an enclosed vacuum chamber. Environmental exposure to the toxic chemicals found in the hard-chrome plating process is completely eliminated.

Did you know?

Hard chrome plating is now banned by EU/REACH regulations and is impacting businesses around the world, including those exporting into the European Union. FortiPhy™ technology is fully compliant, making it your ideal alternative to hard chrome plating.

fortiphy™ xvd

surface enhancement options

FORTIPHY™ XVD

Chromium Nitride

FORTIPHY™ XVD

Aluminum Chromium Nitride

FORTIPHY™ XVD

SILICON Carbide

FORTIPHY™ XVD

CrN + PLASMA ION NITRIDE

FORTIPHY™ XVD

AlCrN + PLASMA ION NITRIDE

FORTIPHY™ XVD

diamond-like carbon