PROBLEM

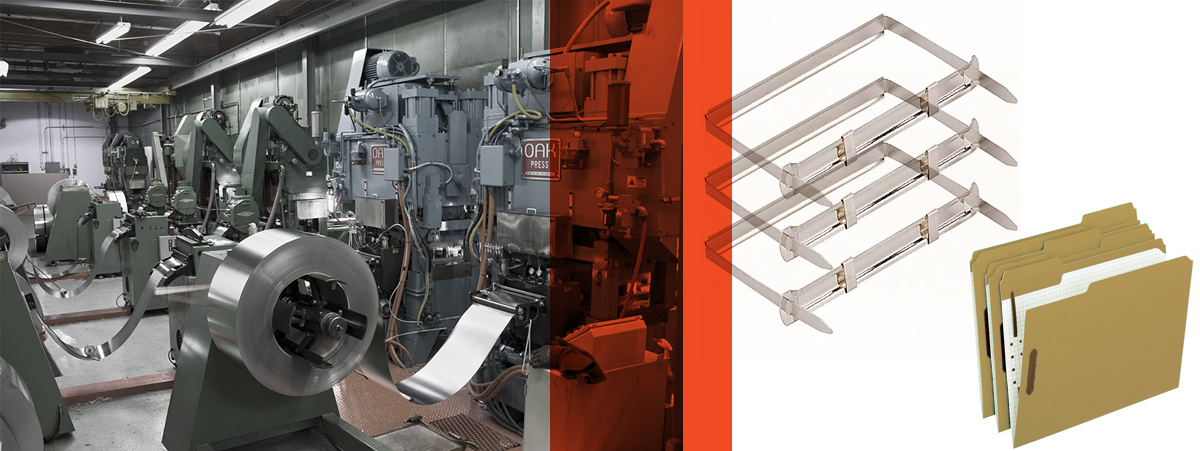

Vanguard Tool & Manufacturing, a stamping and tool and die company, produces a variety of fasteners for more than 100 customers. Vanguard uses steel and carbide tooling to process about 80 tons of steel per day. The plant was having difficulties with the breakdown of form dies, and some shapes lost their consistency as punches became chipped.

Solution

Company representatives asked Phygen to apply FortiPhy XVD to the tooling, then tested their performance. The results were dramatic and immediate. Tooling treated by Phygen lasted twice as long as the punches and dies Vanguard had been using. Once a form becomes worn, the company wire-EDMs the tools and sends them back to Phygen for new surfaces.

It really is possible

FortiPhy XVD has a low coefficient of friction, which helps extend service life. Punches stay hard and corners come out consistently sharp. Vanguard can have longer production runs—often for two months. With a daily output of up to 4 million pieces, downtime is expensive. Phygen technology contributes directly to the bottom line, year after year.

unit increase

“On a sharp corner punch in the tooling, after about 1.2 million hits, we would have to pull it out and resharpen the punch. Now, with the Phygen surface treatment, I can have a full run and not have any issues.”