PROBLEM

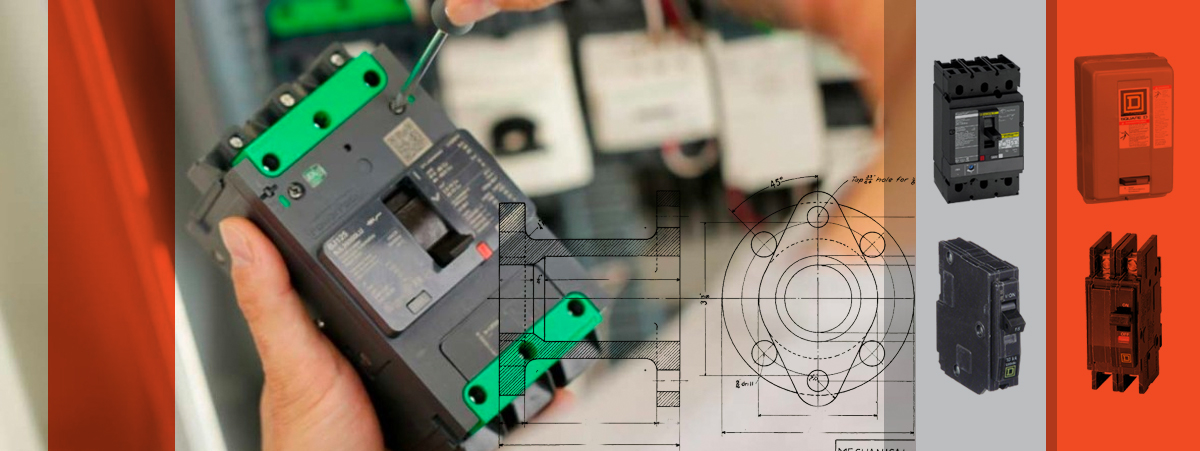

Square D Company of Lincoln, NE, provides injection and injection compression molding of thermoset components, often using highly abrasive compounds with glass fiber content. “Over the years, we have tried a wide variety of surface treatments to extend tool life,” says John MacKichan, molding manager. “But even with common coatings, tooling wear still is a major issue.”

Solution

Square D tested Phygen surface treatments on its high-wear tooling components, such as gate inserts and liners on injection compression molds. The company found that FortiPhy XVD technology did not degrade fine surface finishes or create any dimensional tolerance issues. “FortiPhy seems to work extremely well—even with our abrasive materials,” says Chad Nadgwick, tool room manager.

It really is possible

At Square D, high-wear molds would normally be pulled for repairs after 12 months of production, but the FortiPhy surface treatment appears to have significantly extended the available production life of the tooling. Square D expects this success to provide benefits of cost savings from decreased tool replacement and part quality enhancements. Nadgwick calls it “pretty remarkable.”

“We mold highly abrasive compounds with glass fiber content ranging from nine percent to 25 percent. FortiPhy XVD makes a significant difference.