PROBLEM

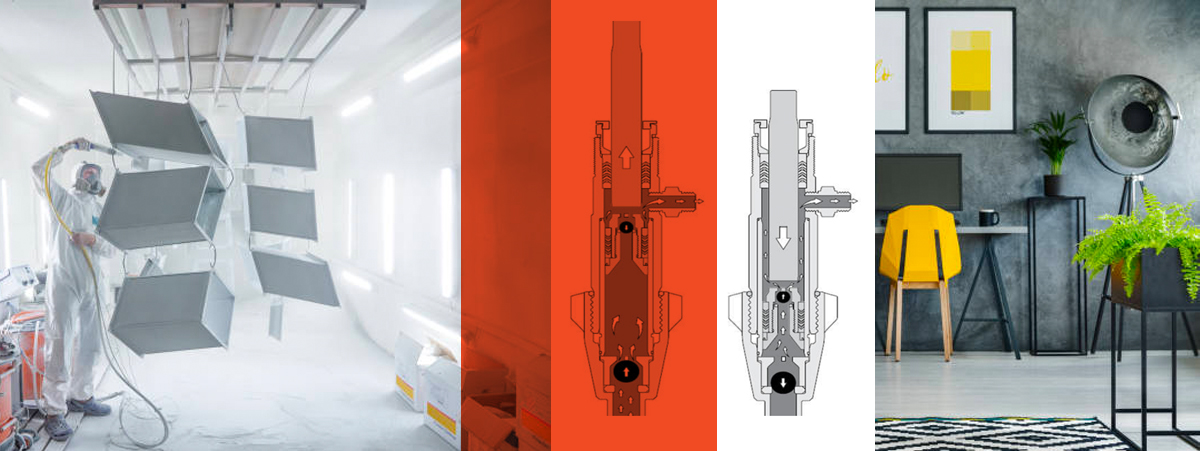

A large manufacturer of metal office furniture uses a sophisticated painting process with high-pressure pumps feeding airless applicators. The pistons, 13 inches long by 1.25 inches in diameter, are custom made, in house. When they fail, production stops until a replacement is installed, lines bled, and the system pressurized. These pumps had been a serious maintenance bottleneck.

Solution

Each of eight pump pistons delivered hundreds of gallons of abrasive paint over their service life, which until then had been less than four months. The company decided to test FortiPhy™ XVD technology and sent a set of pistons to Phygen for treatment. The treated pistons ran smoothly for more than a year with no pressure loss.

It really is possible

This factory’s trial is still ongoing, but so far has proven that FortiPhy XVD technology can outperform other available options in reducing abrasive wear. According to the plant manager, “The Phygen coating process appears to have a much finer quality and better surface finish than other coatings. We expect to double the life of these critical parts.”

life increase

“Piston scoring led to internal leakage and pressure loss. The pumps worked harder until they couldn’t keep up with demand. Thanks to FortiPhy XVD, not any more.”