PROBLEM

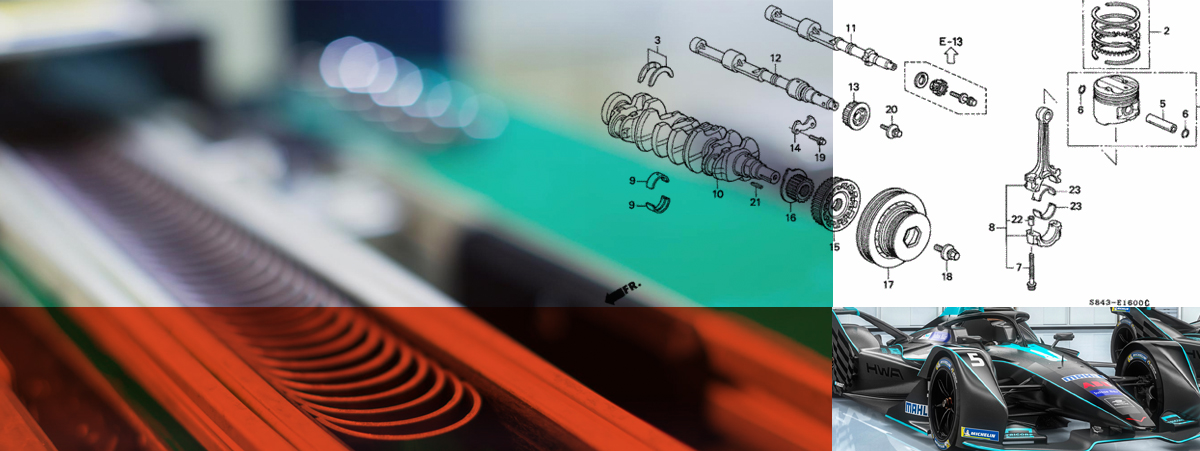

Glacier Vandervell Bearings, a division of Mahle Engine Components USA, makes bushings and thrust washers for automotive engines and transmissions. Starting with 1008 or 1010 steel in coil form, the plant casts about 40 different alloys, including aluminum, tin, lead-tin, and lead-free Clevite materials. When dies need redressing during a press run, the downtime can be expensive.

Solution

Thermal diffusion coatings are applied at temperatures greater than 1800°F, which can cause tooling to warp. When this happens, the tooling cannot be salvaged and must be discarded. Jim Pasquale, supervisor of tools and design services, and Ron Saling, tooling supervisor, chose FortiPhy™ XVD technology for its performance characteristics and because it is applied at lower temperatures.

It really is possible

“Aluminum is really tough on tools,” Pasquale says. “Putting aluminum on the steel back transforms the steel into a real metallurgical nightmare.” FortiPhy XVD creates a polished surface with high lubricity. The Phygen treatment increases durability and toughness while reducing friction, wear, and corrosion. Saling says “We simply have not run into any warping with this process.”

“The press operator is actually my customer. When it comes to how good something is or how long something lasts, the operators let me know.”