PROBLEM

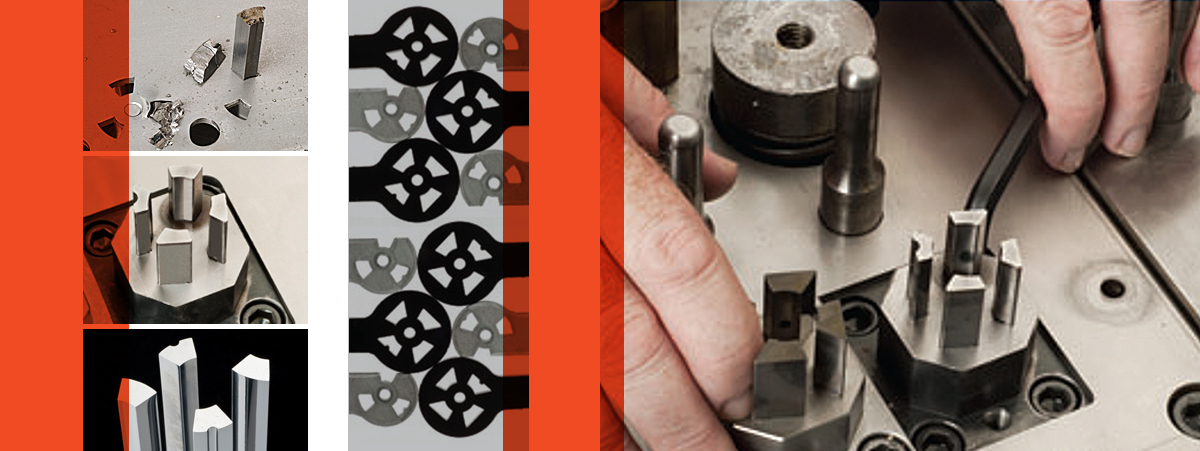

Cowles Stamping, Inc., a Tier 2 automotive supplier and subsidiary of C. Cowles & Company, experienced punch breakage on a progressive-die job after only a couple thousand hits as punches caught in material. Severe galling on the sides of the punches also caused premature failure as the punch ends would weld to the press, then rip off.

Solution

After trying other stamping tool treatments with little or no success, Cowles turned to FortiPhy™ XVD technology. Punch edges now stay sharp throughout production without the need for re-sharpening, though the Phygen technology does allow it if needed. By minimizing breakage, the FortiPhy XVD has reduced the need to repair or replace punches, or to interrupt production.

It really is possible

With FortiPhy XVD, punch life increased from an average of 3,000 pieces to 16,000 pieces between sharpenings.

Producing a new punch took 9 hours on the wire EDM, plus a couple days to send the punch out for coating. A broken punch meant production lost a week. Not any more.

“Along with being stronger than other treatments, the FortiPhy XVD-treated punches no longer catch in the material. The lubricity is spectacular.”