industries

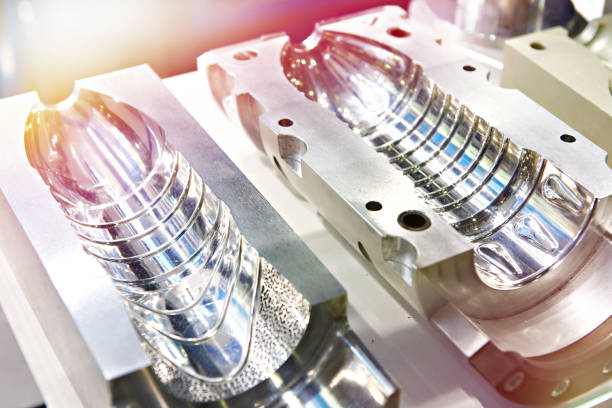

die casting

FortiPhy™ XVD:

a true breakthrough in tooling performance

Conventional PVD coating technology has has not kept up with modern production challenges. Between maintenance costs, sub-optimal tool life, and the down-time associated with die production, tooling represents a significant cost for the die casting industry. You deserve better.

FortiPhy™ XVD is the next-generation technology you’ve been waiting for, delivering superior tooling performance, and endurance that lasts from 3X to over 88X longer, dramatically lowering maintenance costs.

FortiPhy™ XVD can be applied to any die casting tool

- Critical inserts

- Gate areas

- Heavy washout areas

MaXXshot Duplex Process:

- Solvenite Deep Diffusion is the first step, and the KEY to MaXXshot’s success. Solvenite diffuses deep (.015- .020 case depth) with no white layer and no need to polish. Solvenite adds compressive strength and ductility, protecting die steel during thermal expansion and contraction. Prolong’s ability to achieve superior adhesion (between diffusion & top coat) eliminates chipping & flaking, which plagues other duplex coatings

- Hard Multilayer Vacuum Coating Metallurgically Bonds to the Solvenite treated steel. Engineered Exclusively for Die Cast using a matrix of: 1) Tungsten, 2) Chromium, 3) Titanium. Hardness of 3500mv. Our top coating significantly helps with solder and is extremely hard (3500mv) to protect from gate erosion.

Common Questions:

Q: Can we get your MaXXshot over untreated steel? or MaXXshot over nitrided steel?

A: No, there is no MaXXshot without Solvenite first. Only Solvenite’s diffusion allows for a metallurgically bond, and it provides exceptional support for our engineered top coating.

Q: How much build-up will I see with MaXXshot?

A: MaXXshot will add 5-8 microns of thickness (.0002-.0003”) per side. Extensive studies have found this thickness level to be optimal for die casting applications.

NOTE: Solvenite alone creates no size change.

Q: What kind of results have you documented?

A: Customers have reported 10x the life on gate inserts (compared to untreated) and has been outperforming all other common duplex coatings 4x or more.

Very effective against severe washout (gate areas) and solder, even in the most demanding die cast applications.

success stories / die casting

Optimizing Surface Finishes

Sometimes smoother isn’t better.

Pushing the Limits of Design

How to make core pins last, and last, and…

in the news

DIE CASTING ENGINEER MAGAZINE / SEP 2022

Recommended Surface Finishes for PVD Coated Die Casting Dies

Coating die inserts with Phygen’s XVD Nanoperfection Technology helped Mercury Castings reduce solder, extend die life and run faster cycles.

MATERIALS PERFORMANCE MAGAZINE / JUN 2019

Solutions for Corrosion Protection Applications

Phygen’s Fortiphy™ XVD Nanoperfection Technology produces coatings with extremely low levels of defects, verfied by the U.S. Army, which demonstrated it can outperform conventional chromium treatments.

ADVANCED MATERIALS PROCESSES MAGAZINE / SEP 2018

Using FortiPhy XVD to Optimize Surface Properties

Phygen’s unique arc plasma acceleration process reduces the size and number of macroparticles and other defects in the coating for enhanced corrosion protection, wear resistance, reduction of die lubrication, and life extension of forming tools.

FOOD ENGINEERING MAGAZINE / APR 2015

Food-safe, Surface-enhancement Process Extends Component Life

Fortiphy™ XVD Technology increased the lifetime of grinders and other critical wear components from two shifts to many months without peeling or flaking.

DIE CASTING ENGINEER MAGAZINE / SEP 2019

Mercury, Part II: Minimizing Soldering Using High Quality PVD Coatings, Part 2

This second paper in a 2-part series discusses the performance of PVD coatings in casting plants. The paper summarizes applications at Mercury Castings where PVD coatings have been shown to minimize soldering, sticking and dragging.

DIE CASTING ENGINEER MAGAZINE / MAY 2019

Mercury, Part I: Preventing Soldering using High Quality PVD Coatings

The first of two papers discusses factors affecting soldering at Mercury Casting, and concludes die casters should choose a process that produces extremely high quality coatings with low defect contents.