industries

METAL FORMING

FortiPhy™ XVD:

tool performance so superior you’ll think you’re defying the laws of physics.

Between maintenance costs, sub-optimal tool life, and the down-time associated with die production, tooling represents a significant cost for the die casting industry. You deserve better, but conventional PVD coatings have not kept up with modern production challenges.

FortiPhy™ XVD is the next-generation technology you’ve been waiting for, delivering endurance that lasts from 3X to over 88X longer, with dramatically lower maintenance costs.

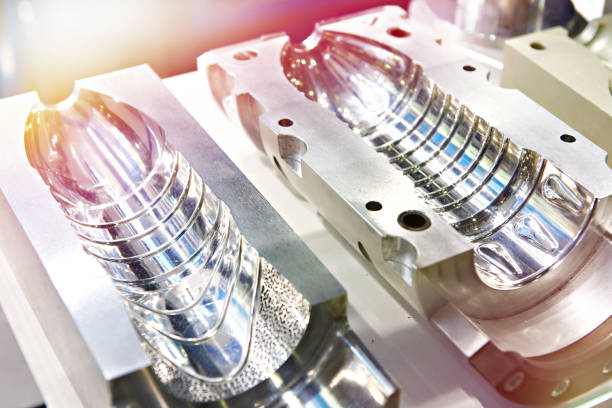

FortiPhy™ XVD can be applied to any metal forming tool

- Critical inserts

- Gate areas

- Heavy washout areas

success stories / metal forming

Switch From Carbide Pays Off

FortiPhy™ XVD technology saves both time and money, big time.

Shiroki’s 20x Increase

Higher reliability reduces rework and inspections.

High Quality, Low Downtime

Phygen helps this automotive supplier deliver a one-two punch.

Pentaflex Ups Productivity 41x

FortiPhy™ XVD makes a strong impression.

Runtime Increased 40x

…and the dies are still running strong.

Low Friction Maximizes Uptime

Dana Corporation stays up and running.

Don’t Stop Now

Deep draw die keeps going, and going…

Never Say Die

Stamper doubles tool life

Phygen Turns Down the Heat

Tool distortion eliminated.

Uptime Is Money

FortiPhy™ XVD doubles die life.

in the news

DIE CASTING ENGINEER MAGAZINE / SEP 2022

Recommended Surface Finishes for PVD Coated Die Casting Dies

Coating die inserts with Phygen’s XVD Nanoperfection Technology helped Mercury Castings reduce solder, extend die life and run faster cycles.

MATERIALS PERFORMANCE MAGAZINE / JUN 2019

Solutions for Corrosion Protection Applications

Phygen’s Fortiphy™ XVD Nanoperfection Technology produces coatings with extremely low levels of defects, verfied by the U.S. Army, which demonstrated it can outperform conventional chromium treatments.

ADVANCED MATERIALS PROCESSES MAGAZINE / SEP 2018

Using FortiPhy XVD to Optimize Surface Properties

Phygen’s unique arc plasma acceleration process reduces the size and number of macroparticles and other defects in the coating for enhanced corrosion protection, wear resistance, reduction of die lubrication, and life extension of forming tools.

FOOD ENGINEERING MAGAZINE / APR 2015

Food-safe, Surface-enhancement Process Extends Component Life

Fortiphy™ XVD Technology increased the lifetime of grinders and other critical wear components from two shifts to many months without peeling or flaking.

DIE CASTING ENGINEER MAGAZINE / SEP 2019

Mercury, Part II: Minimizing Soldering Using High Quality PVD Coatings, Part 2

This second paper in a 2-part series discusses the performance of PVD coatings in casting plants. The paper summarizes applications at Mercury Castings where PVD coatings have been shown to minimize soldering, sticking and dragging.

DIE CASTING ENGINEER MAGAZINE / MAY 2019

Mercury, Part I: Preventing Soldering using High Quality PVD Coatings

The first of two papers discusses factors affecting soldering at Mercury Casting, and concludes die casters should choose a process that produces extremely high quality coatings with low defect contents.